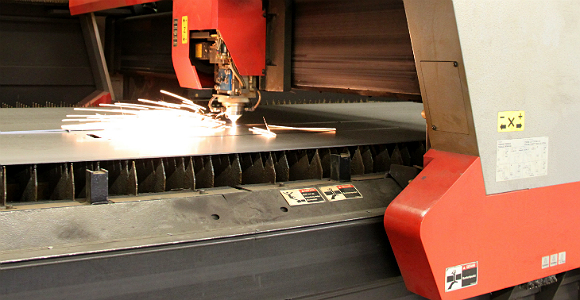

Industrial cutting laser (Photo Credit: Metaveld BV/Wikimedia)

Like most of California, there is a skills gap in the North State region. There are students graduating from high school and community college with knowledge of manufacturing, but not the actual hands-on experience. Recognizing this problem, manufacturers and educators in the area joined forces to make students career-ready the day they graduate.

The “Train the Trainer” program, started last year, trains high school teachers on how to use manufacturing equipment currently in use at local companies. They can then take that knowledge and teach it to the next generation of manufacturers. The first session involved six local CAD, welding, fabrication, and robotics teachers from five different schools.

“If we can get our teachers up to the technology we are currently using, they can then develop a curriculum around that,” said Bill Gaines, senior engineer and chairman of Transfer Flow, Inc., which manufactures aftermarket fuel tank systems in Chico. He acknowledged that the students are tech savvy and are willing learn, but those teaching them are not up-to-date on the current equipment.

Most of the equipment in schools is considered “antique” and not being used out in the working world. “So these kids are learning the technology that’s 20, 30, 40 years old,” added Gaines. “It’s not doing the kid any good. So what we need to do is partner with the schools.”

And, the main issue is access to the equipment. He said the turnover in very expensive equipment makes it prohibitive for schools to invest.

“I’ve gone to nine high schools in the surrounding area and they all have metal fabrication classes,” said Gaines. “Not one has a press brake – not one! Now, how the heck do you teach kids how to fabricate metal when you don’t even have the equipment for it?”

Transfer Flow recently invested in four pieces of equipment, which ranged from $180,000 to $700,000 each. “No school is going to buy the equipment we just bought,” said Gaines.

Professor Jerry Hight, assistant dean of the College of Engineering at California State University, Chico agrees. He works with educators around the North State region to encourage school districts and teachers to take advantage of the “Train the Trainer” program.

“We know that student engagement in STEM-based disciplines, like manufacturing, needs to be elevated within the North State region and that aptitude and work place ability are inextricably linked and we need to do a better job in our K-12 environments in providing education relevancy for our kids,” said Hight.

The “Train the Trainer” program is a good example of the goal on the Summit’s Roadmap to Shared Prosperity to increase exposure to career options in manufacturing by connecting workforce training (K12 through post-secondary) with manufacturers.

Several years ago, the Economic Development Corporation of Shasta County released a report that showed direct output (or economic impact) from one manufacturing job is $271,000, compared to a retail job, which is $75,000. Therefore, increasing manufacturing jobs would strengthen the local economy and training local students to take those jobs would be a bonus.

And, according to Hight, the strategy is to keep local high-skilled workers in the area: “If we educate more of our own, there’s a much stronger likelihood that our own kids are going to want to stay around and propagate businesses and industries that emanate here.”